Faresin Industries, headquartered in Breganze (VI), designs, manufactures and markets mixer wagons and ration analysis instruments for the livestock sector and telescopic handlers for agricultural and industrial use.

The company, founded in 1973 by current President Sante Faresin, combines the tradition of a solid family leadership with the dynamism of an international group with a global presence thanks to a widespread network of subsidiaries, distributors and dealers.

Innovation in the service of our customers’ daily work. A mission that started 50 years ago with the desire to develop, manufacture and sell all over the world technologically advanced machines for the agricultural, livestock, construction and industrial sectors. All of our activities, from design to after-sales services, aim at making our customers’ work more and more secure, efficient and simple.

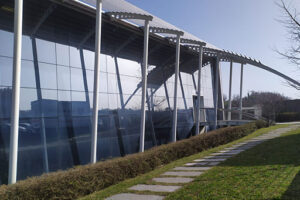

Our gaze is directed towards ambitious goals for the future, our roots stand firmly in the values of our past. Faresin Industries is a company with an international vocation that has developed and grown all over the world over time, but that has always been securely guided by a family strongly linked to its territory of origin. The decision to keep the main headquarters and production plants in Breganze is aimed at bringing significant added value to the local socio-economic fabric, whilst projecting its excellence onto the global market. We believe that people make the difference: for this reason we focus on training our employees and building a solid relationship with our partners, customers and suppliers.

In an ever-changing world where technologies, products and lifestyles change, our founding values have remained the same for nearly 50 years, continuing to be our true strength. Values that do not remain gathering dust on an imaginary bulletin board, but are a dynamic tool that allows us to interpret the present and design the future of the company.

TRANSPARENCY

The company as a glass house; openness to stakeholders. Be clear, unambiguous and true; no ambiguity.

EXCELLENCE

Continuously improving, attention to detail, solving problems quickly, ensuring accurate service, making quality an obsession.

PASSION

Think positively, derive enjoyment from work, believe in what you do, and convey satisfaction to others.

INNOVATION

Promote continuous research on products and services, anticipate the times, devise new solutions, adopt cutting-edge technologies.

ECO-SUSTAINABILITY

Encouraging production processes with reduced environmental impact and making machines that are fuel-efficient and minimize emissions.

SOCIAL RESPONSIBILITY

Act as if the company is your own, be proactive beyond your job description, see yourself as the protagonist of the result, do not use excuses, take charge of problems.

SHARING

Promote discussion; make information a working tool; take everyone’s needs into account; grow together to strengthen as individuals.

Faresin has been proud of being Made in Italy for 50 years. The artisanal care of the product has over time been flanked by industrial production, which has led to superior quality, the result of passion, continuous research and innovation. All of this has allowed us to establish ourselves even outside the national borders, making exports a significant item of our turnover.

Today, Faresin means quality products all over the world thanks to a network of subsidiaries, selected dealers and strategic business partnerships which place the company at the top of the market. From America to Australia, our products stand out for their Made-in-Italy quality and for our after-sales service.

Faresin is near you, all over the world.

A wealth of culture and solidarity that makes the difference: thanks to the synergies deeply rooted in the community we belong to.

A wealth of culture and solidarity that makes the difference: thanks to the synergies deeply rooted in the community we belong to.

We put your work first. We want to be protagonists: for this reason, Faresin products aim to be the right investment for your company.

“Innovation at the service of our customers” has been our mission for 50 years, since the Company was founded.

The evolution is imprinted on the dna of Faresin brand. In its 50-year history, our company has never stopped progressing by making experience the driving force to always push the envelope in the constant search for innovation not only in product but also in process and market approach.

Guido and Sante Faresin found the Officine Meccaniche snc of Faresin Guido and Sante, a mechanical company that works as a supplier of the historic Laverda brand.

The first mixer wagon leaves the company premises: TMR Unifeed, a machine so solid and efficient that it is still present and in demand in our range.

Faresin Srl is born.

TMRS first self-propelled horizontal mixing wagon is born.

TMRV, the first trailed vertical mixer, is born: an innovation destined to be confirmed over time, with the development of the Magnum, Rambo and Twinner models.

The TMRVS mixer wagon is born.

Faresin sheet metal service is born.

The POWER mixer wagon and the TMRSL mixer wagon are born.

Faresin Haulotte and the first telescopic handler range is born.

Faresin Spa is born.

The compact mixer wagon TMRSMART is born.

The new 7-17m telescopic handler and the new LEADER Mono and Double range are born.

Demerger into Faresin Building and Faresin Agri Division.

A new subsidiary is established in Germany, Faresin Deutschland.

Faresin Handlers is born.

Faresin Agri Division and Faresin Handlers merge into FARESIN INDUSTRIES: the "pocket-sized multinational" brings to the world the quality and operational efficiency typical of "Made in Veneto."

Branch office in Poland.

Faresin Far Service Omtm is born.

Faresin France Sarl is born.

New FR telescopic handler range launched.

Faresin Holding is born.

New Range Self-propelled Mixer Wagons PF Line.

Launch of the 1st FULL ELECTRIC Telescopic Forklift at EIMA 2018.

Global market launch of the 6.26 FULL ELECTRIC.

New branch Germany North.

New FS series of telehandlers launched.

New FULL ELECTRIC Big Range from 14 to 17 m.

Self-propelled 36-m3 3-auger mixer wagon with Ecotronic technology.

Launching new self-propelled mixer wagon 1.14B Full Electric.

Faresin INDUSTRIES celebrates its 50th anniversary with an international convention, "Let's Celebrate the Future," held at its Breganze plants, involving more than 400 participants.

Nella proposta progettuale il team R&D Faresin sarà impegnato in attività di ricerca industriale e sviluppo sperimentale. Le stesse saranno portate a termine mediante l’apporto intellettuale di tecnici interni all’azienda, avvalendosi del supporto di specialisti esterni, tra gli altri: Service Group R&D, dell’Università degli studi di Padova. Il progetto è stato sostenuto dal Ministero delle Imprese e del Made in Italy attraverso la concessione di un contributo diretto alla spesa pari a 1.960.732 € e di un finanziamento a tasso agevolato pari a 1.386.222 €.

Puntualmente, le finalità di progetto si riassumono nei seguenti punti:

• massimizzazione del benessere dell’animale: precision feeding, benessere dell’ambiente stalla;

• elettrificazione dei sistemi di propulsione per carri miscelatori;

• farm del futuro:

• sviluppo della guida autonoma per i carri di miscelazione

• sviluppo di un MES per la gestione del processo: precision farming

• implementazione del calcolo della carbon footprint di processo in real-time analizzata in tempo reale e riferita al litro di latte prodotto

Le attività prevedranno tutti gli step necessari alla realizzazione di una nuova gamma di prodotto: dalla fattibilità, alla progettazione, alla realizzazione e test, una pluralità di work packages sono volti alla realizzazione e validazione di prototipi di carro miscelatore, full electric, anche con guida autonoma e con features digitali che porteranno alla rivoluzione delle attuali pratiche operative del settore di riferimento.

Infine, il progetto rispetta il principio DNSH (“Do No Significant Harm”), di cui all’articolo 17 del regolamento (UE) 2020/852 del Parlamento europeo e del Consiglio, del 18 giugno 2020. La quantificazione dell’impatto ambientale associato alle soluzioni sviluppate nel corso del progetto agevolato viene condotta facendo ricorso a strumenti di LCA (Life Cycle Assessment) grazie alla collaborazione con la società Service Group R&D.