Leader PF Full Electric is designed to make use of the electricity that farms produce in large quantities through photovoltaic or cogeneration plants, and at extremely low cost. At the same time, the machine produces no pollutant emissions, thus reducing the environmental impact of the farm. The use of electrical technology also promotes animal welfare and enables certification of the production chain.

1

Auger

388-494-600 ft³

Cubature

91,3 kWh

Battery Capacity

The performance of the new Leader PF FULL ELECTRIC was the starting point of the project. In fact, Faresin engineers have worked hard to ensure performance quite similar to their respective heat-powered models, while maintaining enough range to complete at least a full day on an average-sized farm. For this reason, the 91 kWh Lithium – Iron – Phosphate (LiFePO4 or LFP) battery integrated with Farmatics telematics for remote control was installed in the rear engine compartment.

Battery charging is done with complete flexibility thanks to the Universal Charge system, a single plug-in interface for 220V single-phase and 400V three-phase supplies. The machine also has a system that recovers energy during braking and accelerator release by storing it in the battery and increasing its range.

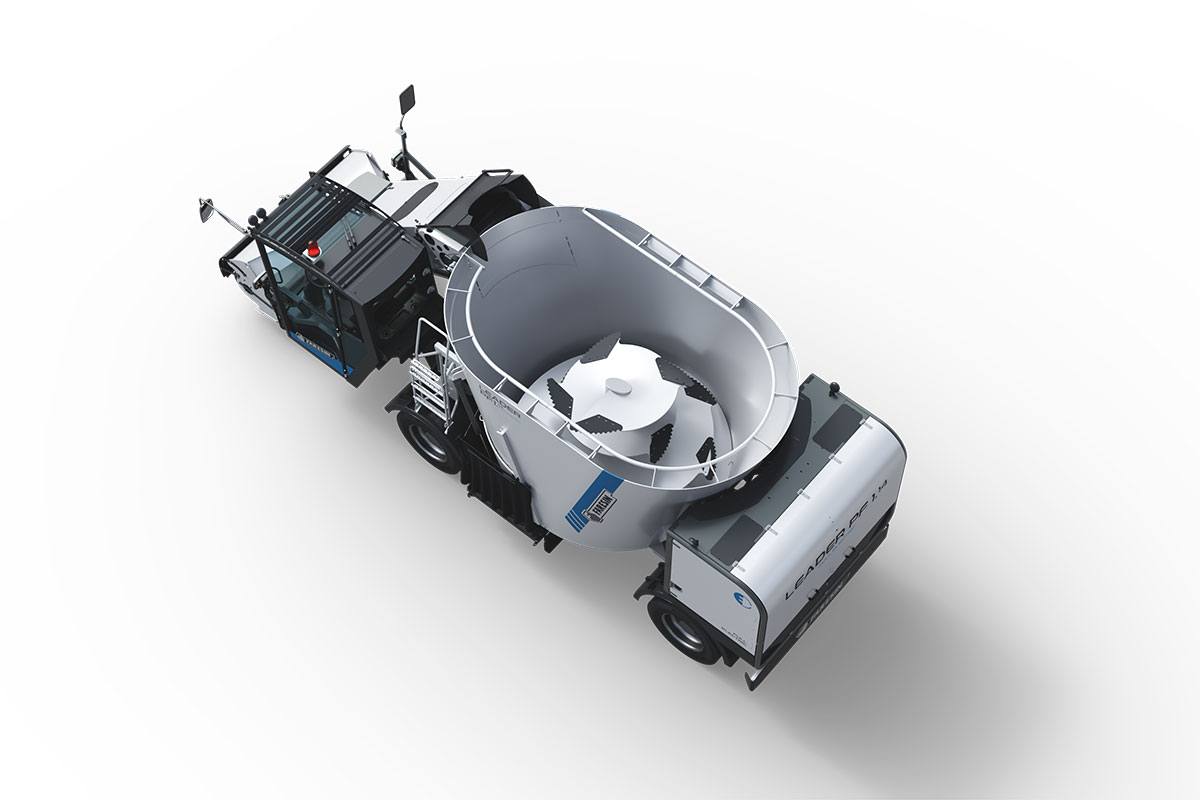

The characteristic geometry of the mixing tub, combined with the special profile of the auger, makes it possible to quickly prepare homogeneous mixes while respecting the organoleptic properties of the fiber. The electric motor, connected to the robust planetary gearbox, guarantees the right power necessary for all types of mixtures thanks to the 8 mixing speeds, which allow you to adapt the machine’s performance to the recipe.

Tractive force comes from a 51 kW electric motor located in the rear axle, which, via a cardan shaft also transmits motion to the front axle. The system has two mechanical gears with shifting from standstill: 1st= 0 – 6.2 mph and 2nd= 0 – 18.6 mph.

The integrated electronic management controls the distribution of power to the various organs, which is dosed as needed to the various utilities, so as not to overload the battery, motors, and inverters, significantly reducing consumption.

In addition, the entire system is monitored by diagnostics that affect all electrical, electronic, and hydraulic parts, including the control instrumentation in the cabin.

Unlike some electrified solutions without silage available on the market, Faresin has decided to equip the new Leader PF Full Electric with a powerful cutter with a width of 2000 mm driven by an electric motor, to allow the autonomous loading of the various components of the recipe.

The special shape of the cutter ensures fast flow to the loading channel, respecting the structure and properties of silage, while the reversible knives remove material quickly and accurately. It is also equipped with an automatic anti-clogging system that, in case of clogging, automatically intervenes on the cutter control and immediately restores its operation.

The PF cab, which has always been a strong point of Faresin self-propelled vehicles, allows the operator to work in a position of absolute control, thanks to large glass surfaces and excellent visibility. Onboard controls are ergonomically arranged to intuitively manage all machine functions.

Main Features

Dimensions

Standard

Optional

Discover Faresin’s full range of Mixer Wagons: the self-propelled Leader PF, the trailed TPF, and the stationary PF and Master. Choose from all models of different capacity sizes, from 1 to 3 augers with vertical or horizontal mixing.

Compila il form sottostante compilando attentamente tutti i campi. Entro qualche giorno lavorativo le verrà inviata la nostra miglior offerta! Grazie

Nella proposta progettuale il team R&D Faresin sarà impegnato in attività di ricerca industriale e sviluppo sperimentale. Le stesse saranno portate a termine mediante l’apporto intellettuale di tecnici interni all’azienda, avvalendosi del supporto di specialisti esterni, tra gli altri: Service Group R&D, dell’Università degli studi di Padova. Il progetto è stato sostenuto dal Ministero delle Imprese e del Made in Italy attraverso la concessione di un contributo diretto alla spesa pari a 1.960.732 € e di un finanziamento a tasso agevolato pari a 1.386.222 €.

Puntualmente, le finalità di progetto si riassumono nei seguenti punti:

• massimizzazione del benessere dell’animale: precision feeding, benessere dell’ambiente stalla;

• elettrificazione dei sistemi di propulsione per carri miscelatori;

• farm del futuro:

• sviluppo della guida autonoma per i carri di miscelazione

• sviluppo di un MES per la gestione del processo: precision farming

• implementazione del calcolo della carbon footprint di processo in real-time analizzata in tempo reale e riferita al litro di latte prodotto

Le attività prevedranno tutti gli step necessari alla realizzazione di una nuova gamma di prodotto: dalla fattibilità, alla progettazione, alla realizzazione e test, una pluralità di work packages sono volti alla realizzazione e validazione di prototipi di carro miscelatore, full electric, anche con guida autonoma e con features digitali che porteranno alla rivoluzione delle attuali pratiche operative del settore di riferimento.

Infine, il progetto rispetta il principio DNSH (“Do No Significant Harm”), di cui all’articolo 17 del regolamento (UE) 2020/852 del Parlamento europeo e del Consiglio, del 18 giugno 2020. La quantificazione dell’impatto ambientale associato alle soluzioni sviluppate nel corso del progetto agevolato viene condotta facendo ricorso a strumenti di LCA (Life Cycle Assessment) grazie alla collaborazione con la società Service Group R&D.

Fill out the form below by carefully filling in all fields. Our best offer will be sent to you within a few working days! Thanks