Leader PF FULL ELECTRIC

Green technology for animal welfare

- capacity 388-494-600 ft³

- 100% electric

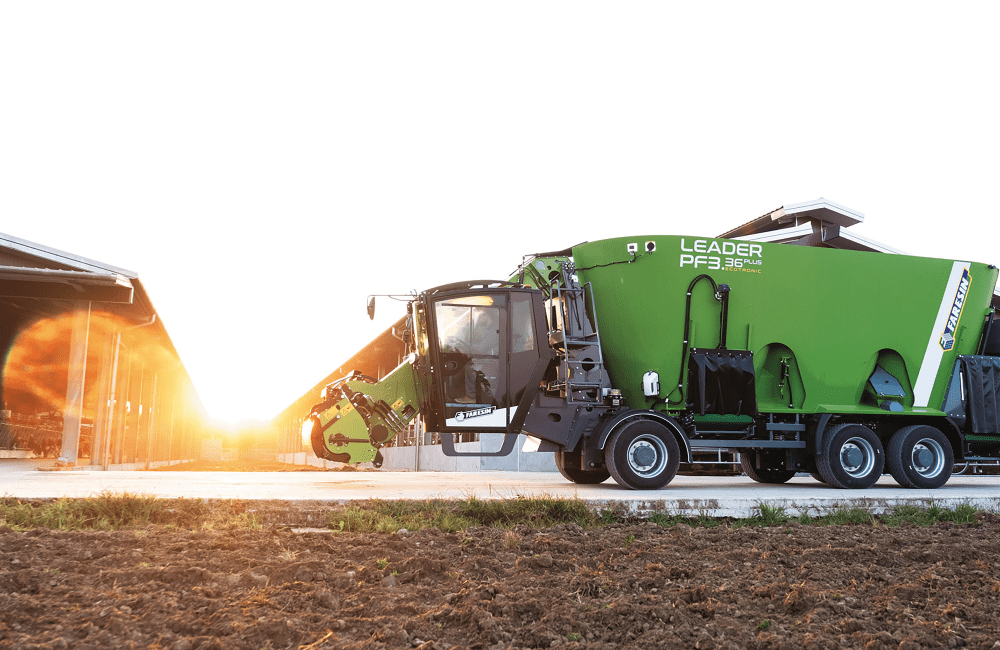

Leader PF Ecotronic

Suitable for large companies

- capacity from 1,059 to 1,412 ft³

- vertical mixing

Leader PF Ecomix / Ecomode

Suitable for medium-sized companies

- capacity from 388 to 1,165 ft³

- vertical mixing

Leader PF Classic

Ease of use and handling

- cubature da 423 a 565 ft³

- vertical mixing